How a stretch wrapping machine supports high-volume packaging

How a stretch wrapping machine supports high-volume packaging

Blog Article

Release Performance in Your Storehouse Workflow With a High-Quality Stretch Wrapping Equipment

Productivity in warehouse procedures rests on the performance of the packaging procedure. The intro of a top notch stretch wrapping device can be a game-changer, promising effectiveness, lowered labor expenses, and reduced human error. With the capability to take care of various tons sizes and cover numerous pallets per hour, these equipments provide a compelling proposition for any kind of company aiming to maximize its operations. What makes these makers such an important possession in warehousing? Let's discover further.

Comprehending the Function of Stretch Covering Machines in Warehouse Workflow

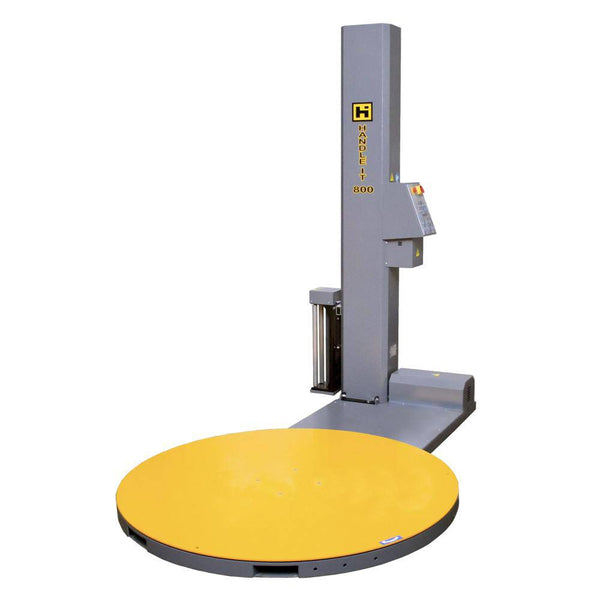

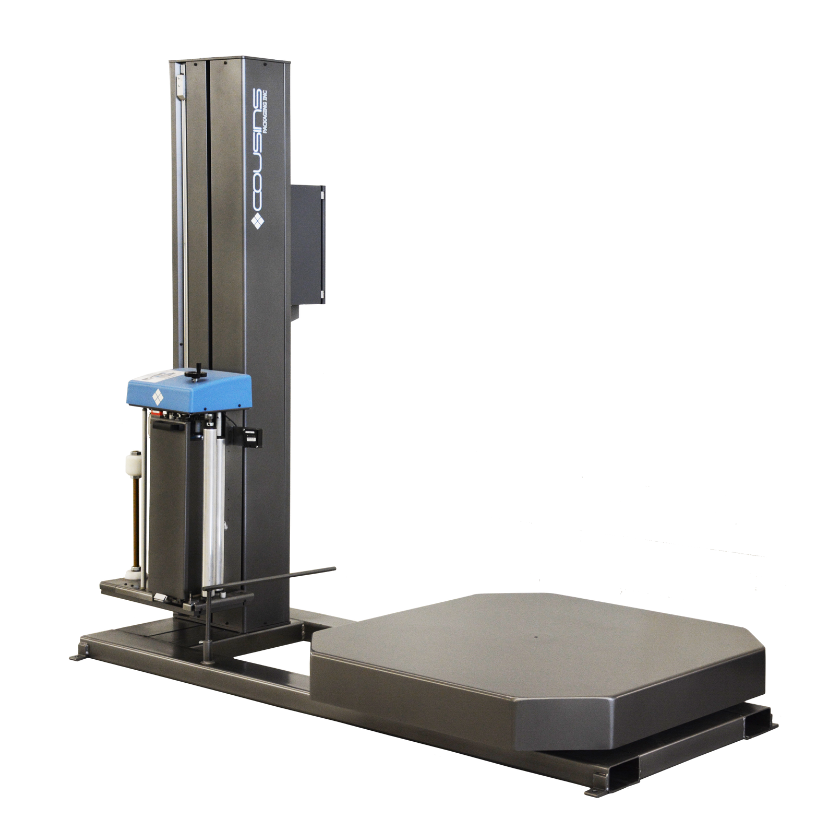

In the large realm of stockroom operations, the relevance of stretch covering equipments can not be overstated. They offer a vital duty in making certain that products are securely and safely bundled for storage or transportation. These equipments use a highly elastic plastic movie around items, snugly wrapping them with each other in a method that hands-on wrapping just can not match.

Stretch covering makers can take care of large quantities of products promptly, significantly speeding up the packaging process. The uniform covering provided by these machines can reduce the threat of meddling or burglary throughout transportation.

Trick Attributes of High-Quality Stretch Wrapping Machines

While there is a vast array of stretch covering machines readily available in the marketplace, high-quality models share specific crucial features that set them apart. These machines are commonly durable, developed to hold up against significant usage without compromising on efficiency. They provide a high degree of automation, enabling problem-free and reliable covering of products.

High-quality stretch wrapping makers also include flexible settings, supplying flexibility to match various product packaging needs. They can manage various sizes and types of loads, guaranteeing a safe wrap every time. These makers are also renowned for their speed, qualified of wrapping countless pallets per hour, thus substantially boosting performance.

One more key attribute is their reliability and reduced maintenance need. Top quality devices are developed to last, minimizing the regularity of breakdowns and the associated downtime. They operate with precision, guaranteeing constant cover stress, consequently minimizing waste and enhancing the presentation of wrapped products.

The Impact of Stretch Wrapping Equipments on Storage Facility Performance

The performance of a stockroom can be dramatically boosted with the use of high-quality stretch wrapping devices - stretch wrapping machine. These machines streamline the product packaging process, decreasing the hands-on labor involved and as a result, the opportunity for human mistake. This makes sure a much more constant and reputable covering process, leading to boosted safety and security of products throughout transport

Moreover, stretch covering equipments can deal with a greater volume of goods in a much shorter quantity of click here for more time compared to hand-operated wrapping. This increased performance can cause better usage of warehouse room as products can be packaged and relocated more promptly. The equipments likewise offer the versatility to suit various dimensions and forms of products, further useful reference improving operational efficiency.

Calculating the Return on Financial Investment for a Stretch Wrapping Maker

Taking into consideration the considerable benefits of stretch wrapping equipments, it's vital to comprehend the economic effects of purchasing such devices. The return on financial investment (ROI) computation is an easy yet effective device to assess the earnings of this investment. The ROI is computed by comparing the cost of the device with the savings generated over a certain duration.

The higher the ROI, the much more profitable the financial investment. Nonetheless, this number must not be the single determinant in the decision-making procedure. Businesses ought to additionally think about aspects such as strategic placement, functional performance, and scalability. In verdict, determining the ROI provides a clear economic perspective to direct the financial investment choice in stretch covering machines.

Real-world Study: Success Stories of Implementing Stretch Covering Machines

Drawing from the financial effects discussed in the previous area, it is equally informing to analyze functional applications and success stories of firms that have applied stretch covering machines in their operations. One such instance is a multinational electronics company which reported a 30% reduction in damaged goods throughout transit after presenting stretch covering machines in their packaging procedure.

Another success tale includes a leading food and drink business. After executing a stretch covering machine, they observed a significant improvement in their product packaging rate, which consequently increased daily outputs and general efficiency.

Finally, a prominent furniture producer was able to lower their packaging material expenses by an incredible 40% after changing to stretch covering devices; they all at once decreased their carbon footprint, making their procedures more sustainable. These real-world study demonstrate the excellent returns and effectiveness gains that extend covering devices can offer warehouse operations.

Final thought

To conclude, investing in a high-grade stretch wrapping machine can substantially boost stockroom procedures. With its capability to lower manual work, decrease errors, and boost room utilization, it significantly increases productivity and productivity. The ROI, coupled with success stories from real-world executions, additionally emphasizes the vital role of stretch covering devices in achieving operational performance and business success.

The intro of a high-grade stretch wrapping equipment can be a game-changer, promising efficiency, reduced labor prices, and decreased human mistake.In the substantial world of storehouse procedures, the importance of stretch wrapping machines can not be overstated.The performance of a stockroom can be dramatically enhanced with the use of premium stretch wrapping machines.In addition, stretch wrapping equipments can manage a higher volume of items in a much shorter amount of time contrasted to hands-on wrapping.In verdict, spending in a premium stretch wrapping equipment can substantially improve warehouse procedures.

Report this page